Case Study - Baitarani Power Hydel Project

Project Description

Hydro-Power is a renewable, economical, non-polluting and environmentally being source of energy. Hydro-Power stations have the inherent ability for instantaneous starting, stopping, load variations, etc. and help in improving the reliability of power systems. There is no fuel cost during the life of the project as hydropower generation is a non-consumptive use of water. The benefits of hydropower as a clean, environment friendly and economically attractive source of energy have been sufficiently recognized. The need for its accelerated development also arises from its capacity of enhanced system reliability and economics of utilization of resources. Environmental impacts of Hydro-Power plants are very different from those of fossil fuel power plants.

As part of power generation Batarani power project limited a subsidiary of RPP group have taken a contract under the guidelines of Grid Corporation of Odisha (GRIDCO) for building 24 MW Hydel Power project at Singhanali Village, Anandpur taluq, Keonjhar district on Baitarani River. We PASCHAL formwork (India) Pvt. Ltd. is very proud to be part of the project.

Project: Baitarani Power Hydel Project Location: Keonjhar District, Odisha

Challenges

- Being in one of the most remote areas there is absolute scarcity to have skilled labour especially in construction of the heavy structure project. PASCHAL modular system being the most user friendly material available in the market, our specialised engineers have provided extensive training program to the lay man and trained them very well to use PASCHAL modular system to execute the project.

- As this was the first time PASCHAL formwork (India) Pvt. Ltd. is working for Hydel Power project, our engineers have studied every aspects involving construction of Hydel project thoroughly.

- There are structure like raft, pier and abutment at barrage structure for which material has to be designed carefully as they will be having only 6 months in a year to do the concrete job during low levels of river. Rest 6 months they will not be able to work as the river levels would rise up. During this peak river flow period the same materials are planned to be used for intake structures as well as for power house. In such a way our technical team was able to succeed in designing the formwork to be utilised from one structure to another structure and designs are appropriately considering their time limitations. This shows the flexibility of PASCHAL Modular Formwork system.

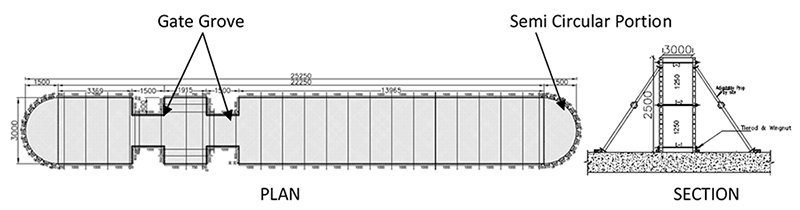

- In this project used with limited quantum of staging material, in spite of the this difficulty our engineers and technical department given possible solutions based on the materials available at site and successfully completed the piers till its top level. (3.75M single casting of the Pier 25M x 3M plan size with gate grove and semi-circular shape in one corner)

- The piers are about 25m in length and the thickness of the walls is about 3m and the edges of the pier are semi-circular with radius of 3m and there are two gate grove locations. Because of versatility of PASCHAL Modular Formwork the erection of pier structure is made possible and with special component called Polygonal filler post are used for making the semi circular portion with the radius of 3m.

- The site being located in remote area, there will be inadequacy of materials keeping this in mind our technical team worked thoroughly and prepared pour sequence for every structures to understand the cycle time of individual structures to be completed during the given time line with limited available materials.

- By using PASCHAL System the rectification works like bulging, slurry leakages and making of formworks for different structures without purchasing extra materials is achieved. This shows the accuracy of PASCHAL Formwork system at various site conditions.

- Our team trained the site team as well as labours on effective and successful use of PASCHAL Formwork System for various structures available at site like piers, intake walls, intake piers and raft etc.

- In spite of many difficulties faced at site location our engineers and technical department have successfully guided the site team in timely manner in completing the site objectives and achieving their goal.

Benefits

- Total Formwork area for this project is about 50,000 sq. m and PASCHAL Supplied Formwork area is about 630 sq. m because of the product quality to be in repetitive nature, 80 repetitions can be opted in this project, being a infra project achieving 80 repetitions indicates material is well utilized.

- Because of the product quality and versatility can be opted in this project.

- As the product is well designed for load bearing capacity, minimum supporting will be sufficient according to the structure. Walers and other supporting elements can be avoided.

- No usage of skilled labour is required as the system is provided with predefined provisions for key bolts and tie rod for appropriate panel sizes.

For further information,

visit: www.paschalindia.com