Managing Geological Complexity In Engineering And Construction Of Tunnels

Rakesh Khali

Group Project Manager

HCC India

Prior estimate of uncertainties and risks involved in the construction process is central to decision-making in underground construction and tunnelling projects. In such projects, a significant part of uncertainties results from unknown geological conditions; thus, timely calculation of risks and action required is vital to mitigate geological risks. Continuous updating of geological models, readjustment of excavation and support to actual ground conditions, control all geological risks at the site. Further, adopting appropriate excavation technology, proper sequences, dependable support and auxiliary measures mitigate the geological risks to a great extent.

Naveen Bahuguna

Dy. General Manager

HCC India

The present paper discusses advance identification of geological risks on the basis of continuous updating of geological model of the site, design updating and measures applied to reduce the risks in the Twin-Tail-Race Tunnels of Tehri Pumped Storage Hydro Project in the Indian Himalaya. The paper also underlines the meticulous construction planning, on the spot resolution of the problem and visualisation of geological risks involved at every stage of design and execution.

Introduction

The Twin-Tail Race Tunnels of 9.1 m diameter each and 1 km long for Tehri Pumped Storage Project, are designed to discharge water from each turbine of 4-250 MW to a downstream reservoir and from there, back up to an upstream reservoir with the help of reversible pump turbine units. Both the tunnels are to be excavated using ‘heading and benching system’ and the ‘drill and blast methods’.

The rock characteristics influence the design and construction of any tunnelling project, which in turn are defined by a set of geological parameters that are estimated to emerge during surface and subsurface investigations. Therefore, before starting the construction and finalising design of any tunnel, it is mandatory to develop an overall geological model of a tunnel, the nature of which has been prescribed during the surface and subsurface investigation. In this project, to finalise a realistic geological model for these twin tunnels, it was found that the major tools to finalise it were: designs of support measures, select excavation patterns and calculated rounds of excavation in each rock class; these tools which were used discreetly, minimised the geological risks during tunnelling.

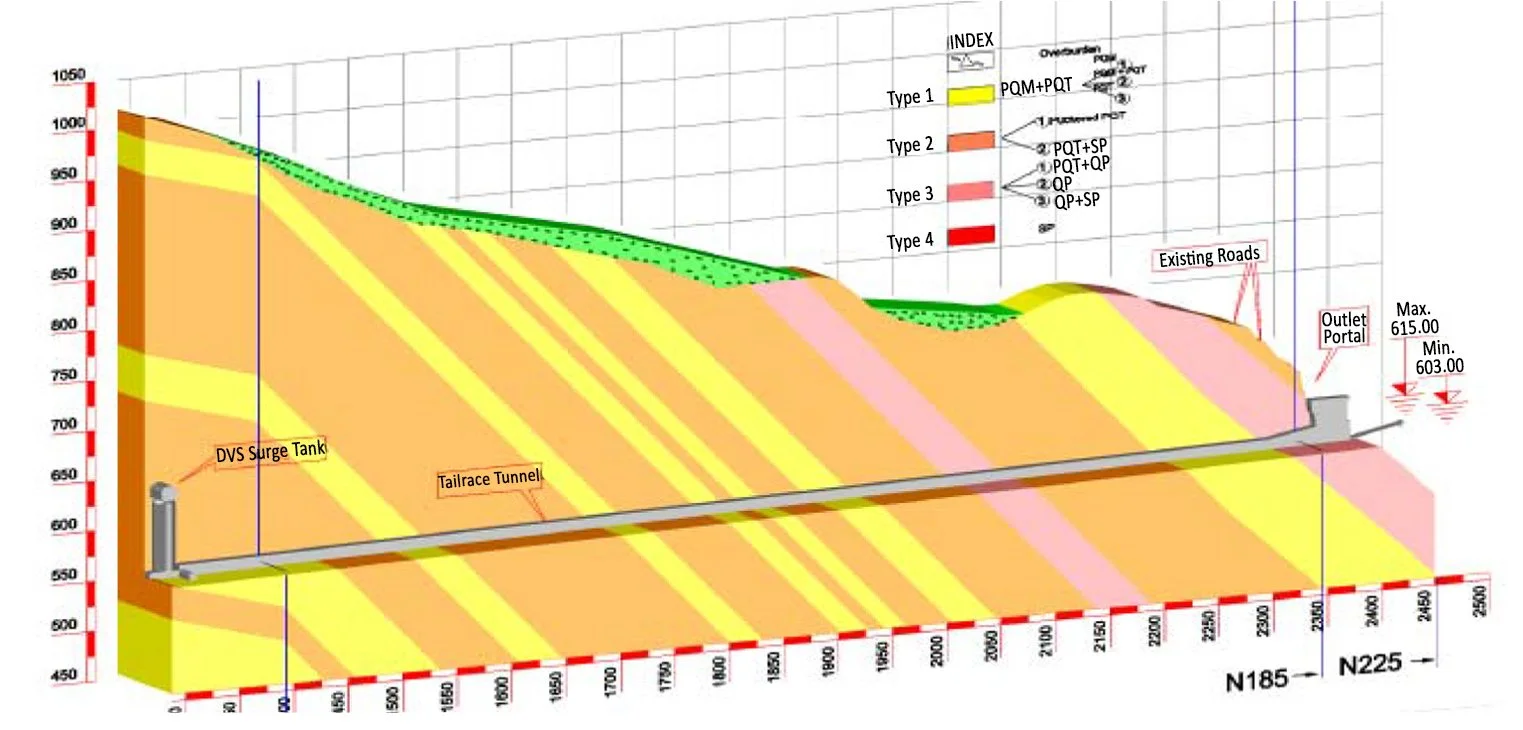

Fig 1: Layout of Tail Race Tunnels

Further, the model was updated with the progress of the tunnel construction and kept an eye on the geological conditions emerging with each round of excavation. Thus, the potentials of severe geological risks were pre-empted.

Geological Model Of The Tunnels

The alignment of the Twin-Tail-Race Tunnel runs through the folded sequence of the low grade metamorphic rocks of upper Chandpur formation of Jaunsar group. The entire sequence appears to be monotonous in composition with variable proportions of argillaceous and arenaceous constituents, and is therefore based on the predominance of particular constituent layers of the rocks of the TRT’s, differentiated into four main rock units: Phyllitic Quartzites Massive (PQM), Phyllites Quartities Thinly Bedded (PQT), Quartizitic Phyllites (QP) and Sheared Phyllites.

A longitudinal profile along the tunnel alignment was derived from the three-dimensional geological model (Fig. 1). Geo-technically speaking, the similar units based on geo mechanical properties, structural properties and groundwater situations were carefully established, thereafter key parameters were obtained from the field investigations and laboratory tests to characterise the rock mass were conducted.

Fig. 2: Geological Model of Tail Race Tunnel

By combining this data with the system factors such as stress conditions, relative orientation of discontinuities of tunnel axis, the influence of ground water, and shape and size of planned tunnels, the behaviour of the rock mass around unsupported excavation was determined and due support system for the each model was designed.

Among the four rock units depicted above, the tunnelling in Phyllitic Quartizite Massive and Quartzitic Phyllite (thinly foliated) was good to fair. However, the tunnelling through the Quarzitic phyllites and Sheared Phyllites belonged to ‘poor’ to ‘very poor’ tunnelling conditions category.

To explore the extension of these various rock units along the tunnel alignment and to minimise geological risks in the process, detailed surface geological mapping and selected geotechnical exploration was carried out, and percentage and zones of each rock unit was established well ahead of the tunnelling.

Fig. 3: Tunnel Excavation with Heading and Benching Sequence

Design Of Support System

Planning and design decisions on tunnels are strongly influenced by the quality and quantity of geological information available before construction starts; this information has a significant impact on controlling and minimising the geological risk of tunnelling.

Considering the complex geological conditions, and bigger diameter of tunnels, it was planned to excavate both the tunnels with ‘heading and benching method’ to minimise the excavation influence of one tunnel upon another.

As per the geological model of the preconstruction phase, it was assessed that the maximum portion of the tunnel would cross through fair to poor rock class and through few intermittent zones of very poor rock class of Sheared Phyllites. Therefore, the support system was designed considering the parameters for different rock units (Fig. 4, Fig. 5 and Fig. 6).

The geotechnical parametric analysis was carried out in situ and the lab test results were obtained. Also, a range of design parameters were determined for each rock segment, and the behaviour of the tunnel and the design of a suitable support system was analysed. As a result, a conservative design was adopted based on the worst expected geotechnical parameters of the rock mass of the proposed tunnel.

The types of the support systems and quantity thereof was adjusted and revised according to the recorded deformation and potential failure-mechanisms of the rock mass.

Prediction Of Ground Condition

Continuous face mapping along with the tunnelling was helpful in controlling over excavation, updating drilling and blasting designs, and finalising the round length through the geological condition encountered. Further, there are far better possibilities of observing the character of the rock and its mass for assessment of interactions between excavation and the tunnel ground during the tunnelling itself than those during any preliminary site investigations. Therefore, continuous recording and updating geological conditions by face mapping provided a space for further improvement in detailing of the existing geological and geotechnical model.

The following typical examples from the daily observations provide an idea about the additional measures taken at the site, which contributed to safe and economical tunnelling:

Documentation of drill cutting during the face drilling ahead of the tunnel face for blasting

Evaluation and geological interpretation of the drilling data

Geological interpretation of the deformation monitoring data

Interpretation of the ground water model

Adjusting support and excavation sequence to the actual geological and geotechnical condition

A series of recorded logs and images of the successive excavation faces allowed prediction of the rock mass structures and of the quality of its representative volume, ahead and around of the face. This, combined with structural geological evaluation, led to a reliable geological model, which in turn formed the basis of predicting the ground behaviour. This became the basis for determining the requisite construction measures.

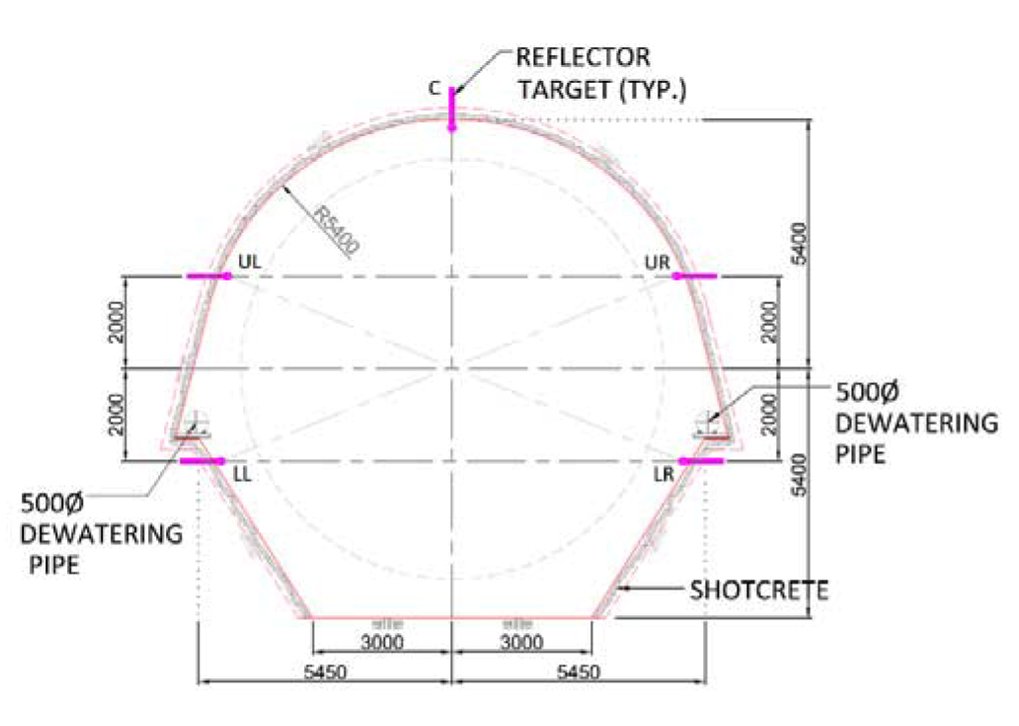

Fig. 11: Tunnel Instrumentation

Tunnel Monitoring

Monitoring of tunnel convergence was carried out parallel with the tunnel excavation, and convergences were measured with the help of optical targets placed along the tunnel perimeter at selected locations. As such, no significant movement was recorded during construction; and it was found that the tunnels were behaving as per the design-assumed conditions. An appropriate support system was therefore provided for each rock class, which ensured sufficiency to support the tunnels.

Excavation Of The Round Length

The selection of the round length for heading and benching of tunnels was determined by length of the tunnel in the different rock classes. The round length in each rock unit was selected, considering the basic parameters determined by geological conditions, shape and size of the tunnels, excavation methods and their impact on the stability of each rock unit.

Further, to invoke the desired rock movement before installation of the support to the rock arch effects and to enhance the speed of support placement, suitable engineering measures were adopted. All these factors pooled together to determine the stand up time for different kinds of rock classes that can sustain without support.

Conclusion

An adequate geological exploration is the most effective strategy for reducing the effects of geological uncertainty and it is also the basic tool for minimising the geological risk in tunnelling. Un-certainties associated with underground construction can be managed by means of continuous updating of design during subsequent construction stages. In addition, a continuous adjustment and readjustment of excavation support methods suited to respective rock mass condition, contributes to safe and economical tunnelling. Therefore, before starting the construction and finalising design of any tunnel, it is crucial to develop an overall geological model, based on surface and subsurface investigation. It can be concluded that a realistic geological model for these twin tunnels will function as a major tool in finalising the design of the support measures, selecting excavation patterns, deciding the rounds of excavation in each rock class and minimising geological risk during tunnelling.

References

Barton, N., Lien, R., & Lunde, J. (1974). Engineering classification of rock masses for the design of tunnel support. Rock mechanics, 6(4), 189-236.

Brown, R.H.A.: The management of risk in the design and construction of tunnels. Korean Geotechnical Society Tunnel Committee Seminar, pp. 1–22, Korea, 1999.

Hoek, E. (2018). Support for very weak rock associated with faults and shear zones. In Rock support and reinforcement practice in mining (pp. 19-32). Routledge.

Ioannou, P. G. (1987). Geologic prediction model for tunneling. Journal of Construction Engineering and management, 113(4), 569-590.

Priest, S. D. (2012). Discontinuity analysis for rock engineering. Springer Science & Business Media.

Rausand, M. (2013). Risk assessment: theory, methods, and applications (Vol. 115). John Wiley & Sons, pp. 4-6, 2011.

Riedmüller, G. & Schubert, W. 2001. Project and rock mass specific investigation for tunnels. ISRM Reg. Symp. Eurock 2001, Espoo, Finland. In P. Särkkä, P. Eloranta (eds.), Rock Mechanics a Challenge for Society: 369-376.Rotterdam. Balkema

Schubert, W., & Schubert, P. (1993). Tunnels in squeezing rock: Failure phenomena and counteractions. Proc. of the Assessment and Prevention of Failure Phenomena in Rock Engineering, 479-484.

Steindorfer, A., 1998. Short term prediction of rock mass behaviour in tunnelling by advanced analysis of displacement monitoring data. In Riedmüller, Schubert & Semprich (eds), Schriftenreihe der Gruppe Geotechnik Graz, Heft 1.

From - CE&CR January 2020 Issue